The Art of Yarn: An Insider’s Deep Dive into Sock Manufacturing

Having spent years on the factory floor, whenever a client approaches me with a new design, I always start with the same three questions: What’s the material? What’s the needle count? And what’s the yarn count?

To most people, a good sock is just about a nice pattern and soft touch. But as a manufacturer, I have to be honest with you: the soul of a sock is determined the moment the yarn and machine specifications are locked in. It is a strict industrial logic. Today, I want to step away from the dry spec sheets and take you behind the scenes to understand the “Holy Trinity” that decides the fate of your product.

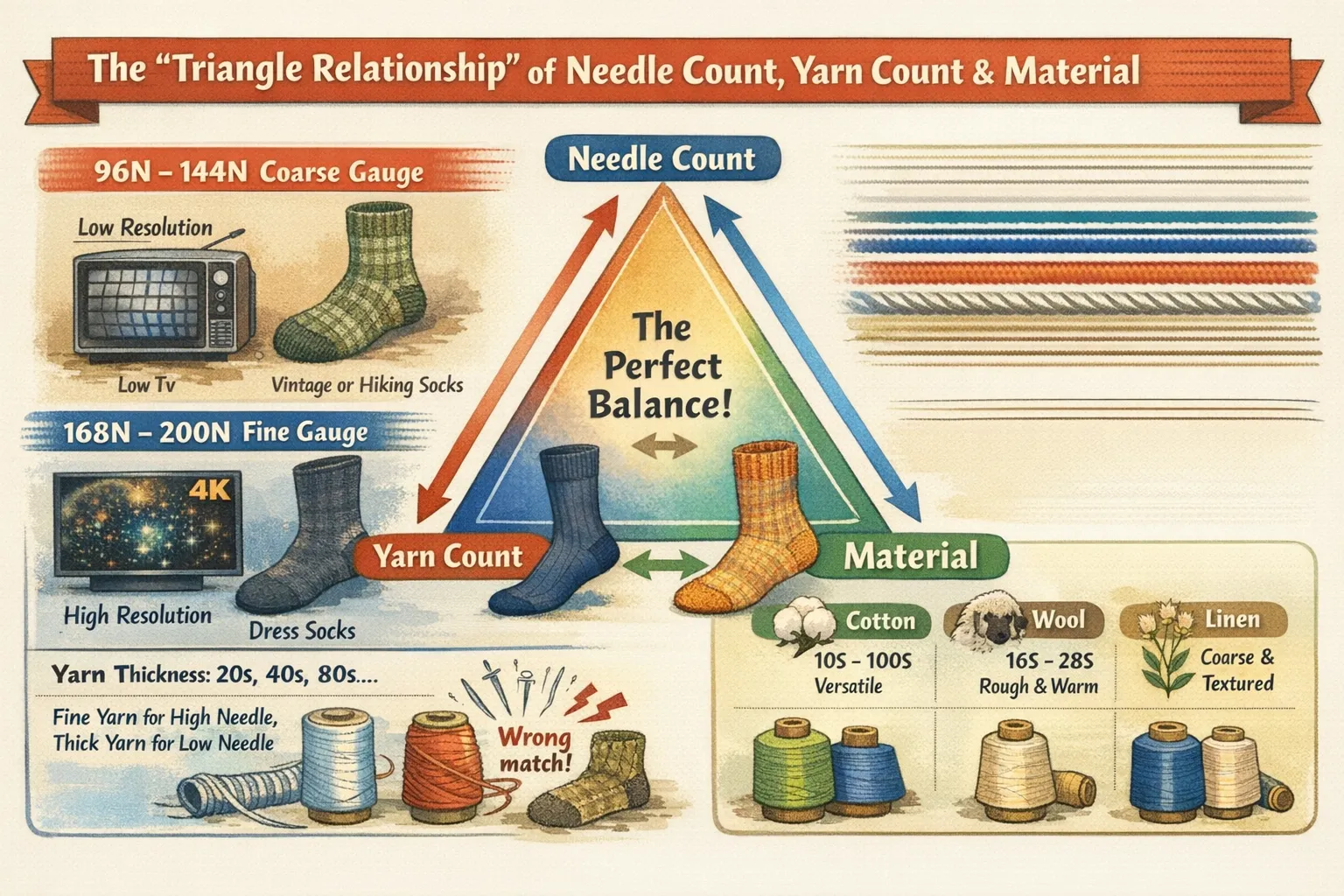

The First Lesson: The Triangle of Material, Needle, and Count

In our industry, Material, Needle Count, and Yarn Count are inseparable. You cannot just mix and match them randomly; they must physically fit together.

First, let’s talk about Needle Count. Think of this as the “Screen Resolution” of your sock.

- 96N - 144N (Coarse Gauge): Like an old TV screen. The gap between needles is wider, creating larger loops. This is ideal for chunky, thick textures like vintage-style or hiking socks.

- 168N - 200N (Fine Gauge): Like a 4K screen. The needles are packed tightly together, creating a surface that is incredibly smooth—perfect for crisp business socks.

Next is Yarn Count, which simply measures the thickness of the yarn (often denoted as ‘S’). This is where clients often get confused, but the rule is simple: Small needles require fine yarn. If you try to force thick yarn into a precision 200-needle machine, the fabric will become stiff as a board, lose elasticity, or simply break the machine’s needles. Conversely, using fine yarn on a coarse machine is like trying to fill a pothole with thread—the result is a flimsy, spiderweb-like structure.**

So, can every material be made into any thickness? No. The physical properties of the fiber dictate its limits.

- Cotton: The versatile all-rounder. It ranges from thick 10S-20S (for rugged wear) to ultra-fine 80S-100S (for luxury mercerized dress socks). It covers almost every needle count.

- Wool: The rugged gentleman. Because wool fibers have scales and a natural crimp, they are difficult to spin into ultra-fine threads. Most wool yarns we use are in the 16S-28S range, which is why wool socks are generally thicker and suited for coarser gauges.

- Linen: The tough guy. It has high rigidity and breaks if spun too fine. We usually use it in lower counts to maintain that unique, dry, granular texture.

- Synthetics: The shapeshifters. Man-made fibers like Nylon can be spun microscopically thin, usually serving as the hidden reinforcement blended with the natural fibers above.

Cotton: From Crop to Industrial Standard

Cotton is the bedrock of our industry. In the early days, Carded Cotton was the norm. It retained short fibers and impurities, resulting in socks that were fuzzy and turned harsh after washing.

Later, Combed Cotton became the entry ticket for quality. The combing process removes short fibers. This isn’t just for looks—it significantly increases Tensile Strength. On our high-speed knitting machines, combed yarn breaks far less often, which directly translates to lower defect rates for your orders.

Then there is Mercerized Cotton. This is a chemical process developed in the 19th century.

🔍 Industry Term: Mercerization

Cotton yarn is treated with caustic soda under high tension. This causes the flat cotton fiber to swell and become round. **The Effect: This structural change reflects light more evenly (creating a silk-like luster) and absorbs dye more deeply (resulting in rich, saturated colors).

If you are creating high-end formal socks, Mercerized Cotton is irreplaceable.

The Synthetic Revolution: Solving the “Sag”

Synthetics are often misunderstood, but they are the greatest revolution in hosiery history. Before Nylon and Spandex, socks had no elasticity and required garters to stay up.

- Nylon (Polyamide): Gives the sock a “Skeleton.” Its abrasion resistance is 10 times that of cotton. We plate Nylon into the heel and toe to withstand friction.

- Spandex (Elastane): Gives the sock “Memory.” It allows the sock to stretch 5-7 times its size and snap back.

The modern golden rule: “Natural fibers for comfort, Synthetics for structure and longevity.”

The Wool Renaissance: Superwash Technology

Historically, wool socks were synonymous with “itchy” and “shrinking.” This is due to the scales on the wool fiber.

🔍 Industry Term: Felting

When wool is exposed to heat and friction, the scales on the fiber surface open up and interlock with each other (like Velcro). This causes the fabric to shrink, thicken, and harden.

Modern Superwash Technology removes these scales or coats them with resin, preventing felting and allowing wool socks to be machine washed. For performance, Merino Wool is king. Its “Heat of Sorption” is a fascinating physical property: as the fiber absorbs moisture vapor, it actually generates a small amount of heat.**

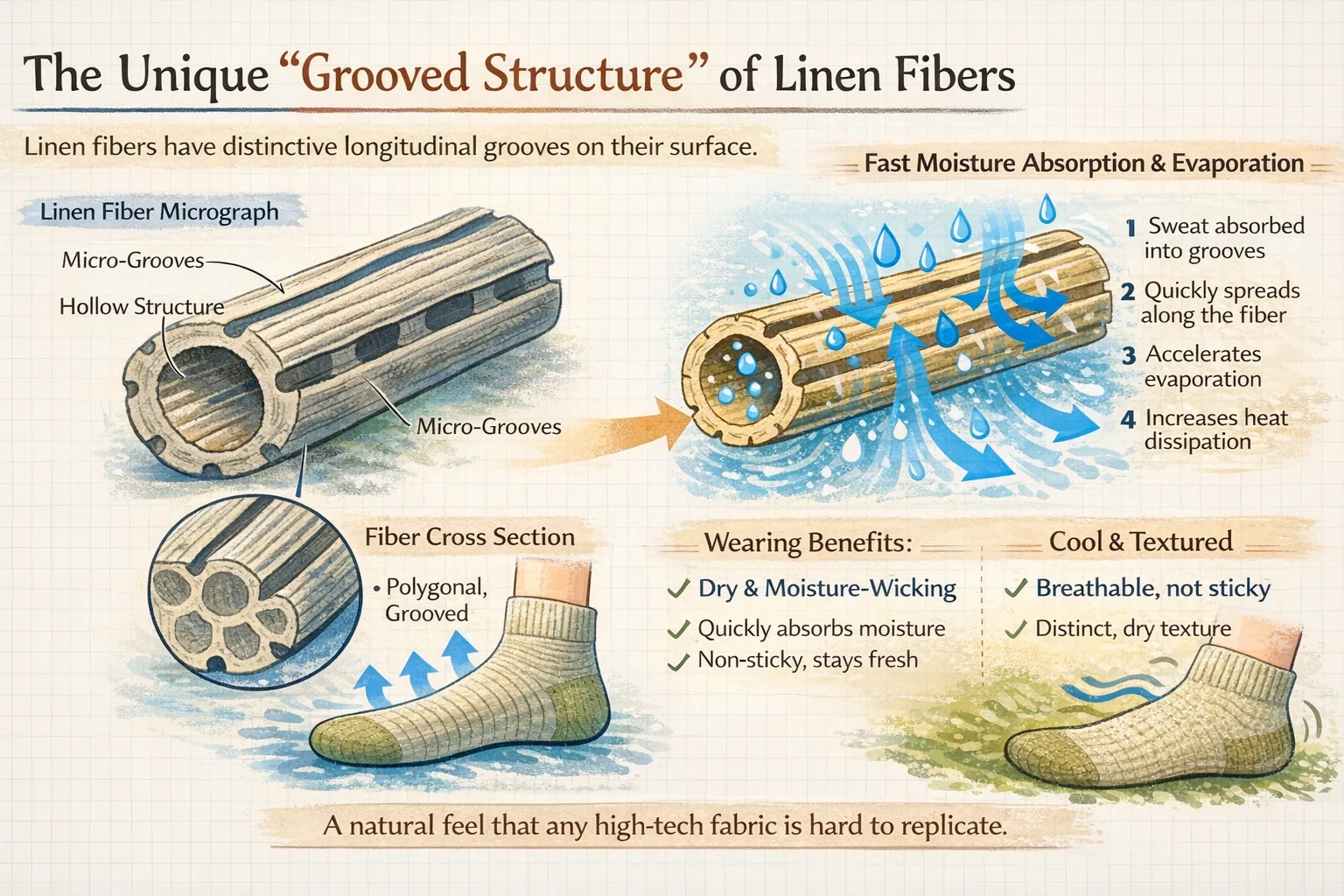

Cashmere & Linen: Balancing Luxury with Physics

Cashmere: Clients often ask for “100% Cashmere,” but I advise against it. The fibers are too fine (14-16 microns) and weak for the friction a foot creates. Our solution is “Engineered Blending”: 10-30% Cashmere for touch, supported by Wool and Nylon for structure.

Linen: One of the oldest fibers known to man. Its unique molecular structure wicks moisture rapidly. While difficult to spin, its dry, “granular” texture provides a cooling sensation for summer socks that no synthetic can mimic.

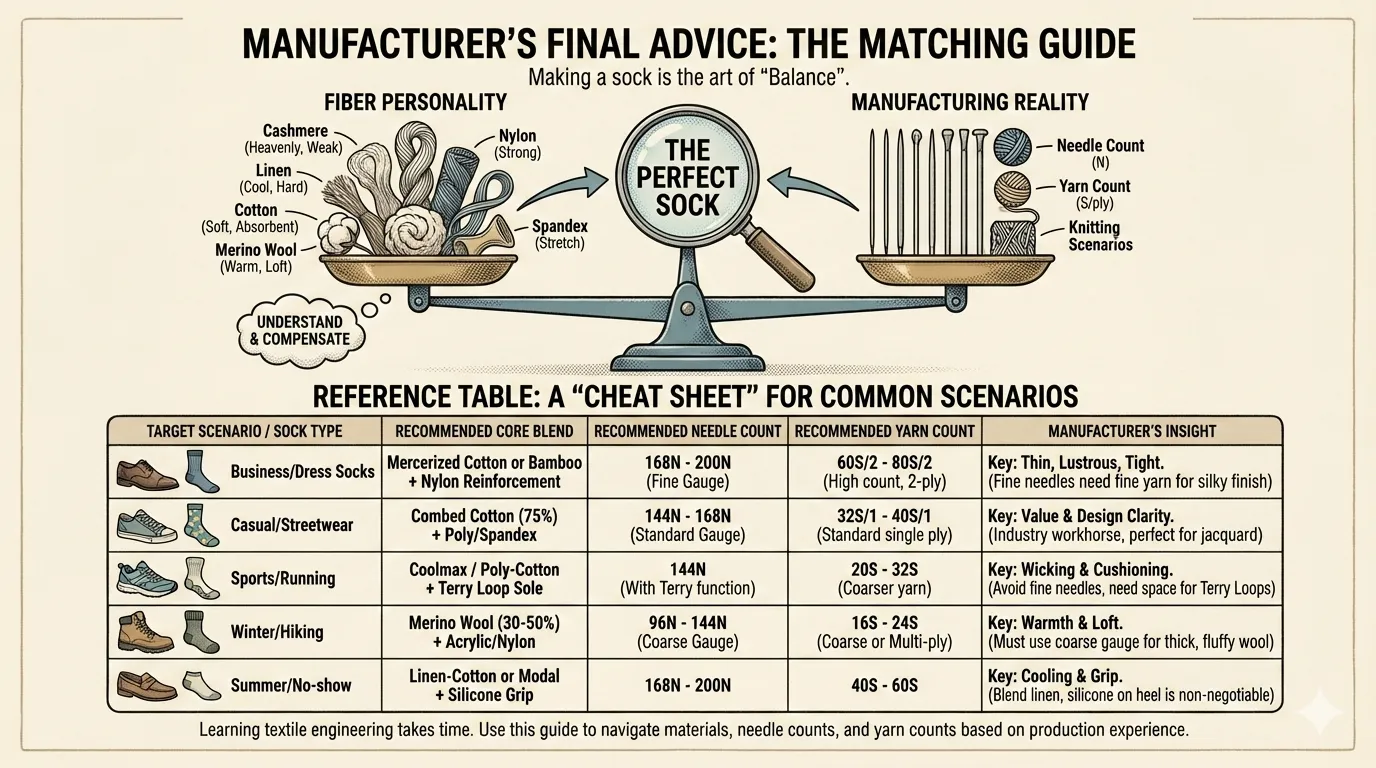

Manufacturer’s Final Advice: The Matching Guide

After all these technical details, I want to circle back to my main point. If there is one thing I’ve learned from years in this business, it is this: Making a sock is the art of “Balance.”

There is no such thing as a “perfect” single yarn.Cashmere feels heavenly but is too weak to walk in alone. Linen is cool and dry but feels hard and lacks stretch. Our job is to understand the personality of each fiber and, depending on the scenario (hiking, running, or a board meeting), combine them to compensate for each other’s weaknesses. Then, we must choose the correct needle count to weave them into reality.

I know that learning textile engineering takes time. To help you navigate this, we have compiled a Reference Table based on our production experience. This is essentially a “cheat sheet” for matching materials, needle counts, and yarn counts for the most common scenarios.

| Target Scenario / Sock Type | Recommended Core Blend | Recommended Needle Count | Recommended Yarn Count | Manufacturer’s Insight |

|---|---|---|---|---|

| Business / Dress Socks | Mercerized Cotton or Bamboo + Nylon Reinforcement |

168N - 200N (Fine Gauge) |

60S/2 - 80S/2 (High count, 2-ply) |

Key: Thin, Lustrous, Tight. Fine needles need fine yarn. We use 2-ply high-count yarn to ensure a silky smooth finish that fits perfectly inside dress shoes without bulk. |

| Casual / Streetwear | Combed Cotton (75%) + Poly/Spandex |

144N - 168N (Standard Gauge) |

32S/1 - 40S/1 (Standard single ply) |

Key: Value & Design Clarity. The industry workhorse. 32S yarn paired with 144N is the “Gold Standard” balance of softness and durability, perfect for jacquard patterns. |

| Sports / Running | Coolmax / Poly-Cotton + Terry Loop Sole |

144N (With Terry function) |

20S - 32S (Coarser yarn) |

Key: Wicking & Cushioning. We avoid fine needles here. We need the space provided by 144N to accommodate thicker yarns that form the “Terry Loops” for shock absorption. |

| Winter / Hiking | Merino Wool (30-50%) + Acrylic/Nylon |

96N - 144N (Coarse Gauge) |

16S - 24S (Coarse or Multi-ply) |

Key: Warmth & Loft. Must use coarse gauge machines! Fine gauge needles are too small for the thick, fluffy wool needed to trap heat. |

| Summer / No-show | Linen-Cotton or Modal + Silicone Grip |

168N - 200N | 40S - 60S | Key: Cooling & Grip. Linen can be stiff, so we blend it with cotton. High-quality silicone on the heel is non-negotiable to prevent slipping. |

Final Word: When you understand this table, you stop seeing just colors and patterns, and start seeing the precise engineering of yarn and needle. If you are ever unsure about a spec, send me your design. I’ll tell you straight away if it will run smoothly on the machines or if we need to tweak the yarn count.