Custom Sock Packaging Explained: From Header Cards to Gift Boxes—Which One Is Right for You?

The packaging is your customer’s first impression of your product. Get it right, and you give your sales an unexpected boost. Get it wrong, and you risk undermining even the best-designed socks. Over the years, we’ve worked with hundreds of brands. Some had excellent sock designs that got dragged down by poor packaging choices. Others had fairly standard products that sold at premium prices, all thanks to thoughtful packaging decisions.

Today, I’m skipping the marketing talk and going straight to what matters. Drawing from our factory’s experience, I’ll walk you through the main packaging options we see in the industry and help you figure out which one fits your product best.

The Classic and Reliable Choice: Custom Header Cards

If you’re not sure where to start with packaging, we usually recommend header cards. This method strikes a good balance across the board.

The origins of header card packaging go back to the late 19th and early 20th centuries, when Western countries shifted from traditional tailoring and general store sales to standardized industrial production paired with department stores and chain retail. Socks moved from being made by households or small workshops to large-scale mechanical knitting operations. Products needed to be differentiated, displayed, and sold on open shelving, which created a direct need for packaging that could be hung and easily identified. This affordable, display-friendly, brand-conscious packaging solution emerged naturally and gradually matured over time.

Even today, header cards remain the most mainstream and widely accepted packaging method in the market. In our factory, roughly seventy to eighty percent of our clients choose this classic approach.

In today’s highly developed offline retail environment, header cards with J-hooks or Euro slots save valuable shelf space while providing ample branding area. They make it easy for staff to hang products on display racks and convenient for customers to grab what they need, fitting perfectly with the open, experiential retail concepts that have gained traction in recent years. In the booming e-commerce sector, the flat profile of header card packaging also makes it easy to slip into shipping bags or boxes.

Of course, this classic packaging format has evolved considerably over the years, and now we have more personalized options to offer.

In terms of paper selection, header cards are no longer limited to traditional white cardboard or coated paper. We now have access to a wider range of modern paper materials, including specialty art papers and textured papers, as well as environmentally conscious options like recycled paper and FSC-certified stock.

For printing methods, the rise of digital printing means that even smaller custom runs can now achieve full-color, custom-pattern printing. If you want a more premium visual finish on your header cards, we can also apply techniques like UV coating, debossing or embossing, and gold or silver foil stamping to specific areas such as your brand logo or text, enhancing the overall visual appeal.

When it comes to attachment methods, the traditional approach uses plastic kimball tags to secure the header card to the socks. The advantage here is durability—no matter how much the product gets jostled during shipping, it stays firmly attached. The downside is that customers often find it difficult to open, usually needing scissors or another tool. A more eco-friendly and user-friendly alternative involves carefully designing and die-cutting the card with special notches so it locks onto itself without additional fasteners. This method is environmentally friendly and easy to open, though it’s not quite as secure as the plastic pin. Currently, the design that balances all these factors best is thread-stitching. Instead of a plastic pin, we use a stitched thread with a special technique that leaves a pull tab exposed. The customer simply tugs the tab to release the packaging. This method combines environmental responsibility with a smooth unboxing experience, and it’s the header card attachment method we recommend most often these days.

Creative Yet Cost-Effective Packaging: Paper Belly Bands (Sleeves)

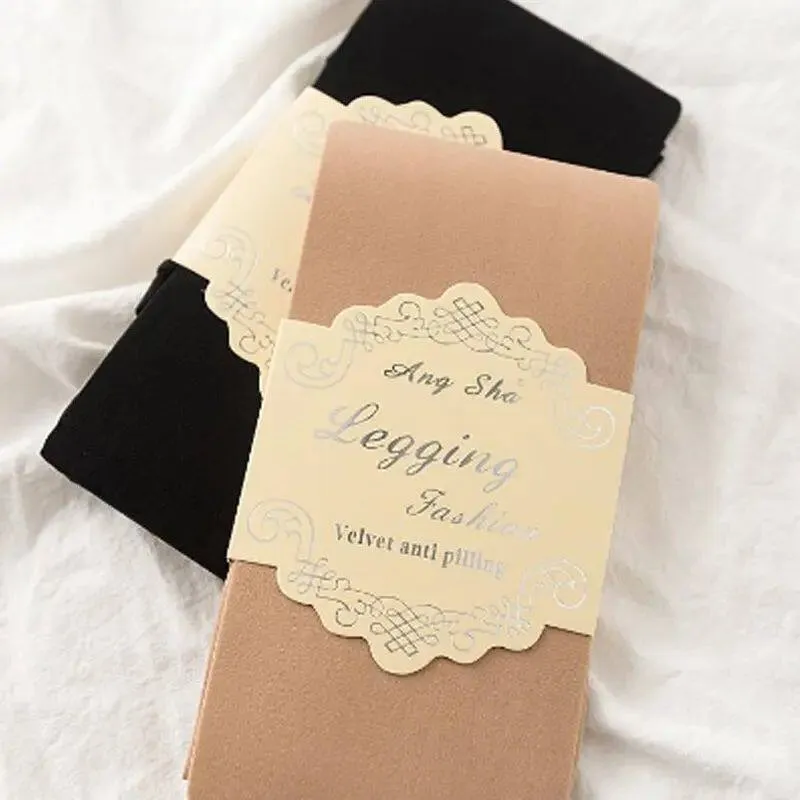

Header cards are so widely used that most consumers probably encounter them on the majority of socks they see, which can make them feel somewhat ordinary. If you want your socks to have a bit more design flair, or if your product might be purchased as a gift, we recommend considering belly band packaging. Belly bands are commonly seen on gift boxes and high-quality hardcover books. They wrap around the middle of the socks like a belt, leaving a large printable surface area that’s perfect for displaying your logo or sharing a bit of your brand story. They give the product a more “gift-like” quality and make it feel more refined and premium. When customers unwrap the belly band from the socks, they experience that pleasant feeling of opening a present. This subtle psychological effect can be quite valuable in marketing.

We typically use a tab-lock structure for belly bands, which doesn’t require any glue, resulting in a clean, polished look that’s also very environmentally friendly. At the same time, the cost is quite low. For clients who want to position their products as premium but have a limited budget, belly bands are a very smart solution.

Premium Custom Packaging: Gift Boxes

Gift box packaging, or fully custom packaging, represents the highest-end option for sock packaging currently available. By customizing the box material, shape, and printed design, you can fully express your brand identity and provide your customers with an exceptional packaging experience. At the same time, excellent custom packaging design can give your market sales real momentum. In 1969, Hanes’ L’eggs brand broke away from the traditional flat cardboard box design and introduced an egg-shaped package that perfectly aligned with their brand, making L’eggs the best-selling pantyhose in America at the time. The L’eggs packaging is now recognized as one of the greatest marketing designs of the 20th century.

However, fully custom packaging boxes involve fixed costs like mold-making, so we generally recommend this option for clients with larger order volumes, which helps spread out the average packaging cost per pair of socks.

But what if you’re a startup brand with smaller order quantities, and the cost of making molds for printed boxes is too high, yet you still want gift box packaging? Thanks to China’s highly developed sock manufacturing industry, you can choose to use high-quality ready-made blank boxes paired with beautifully designed custom adhesive sealing stickers. This packaging approach eliminates mold-making expenses. While you sacrifice some degree of customization freedom, you can still maintain the box’s refined and premium feel.

We’ve handled many such cases at our factory. As long as the sticker design is well-executed, placing it on a plain white box creates a very upscale impression. If you also include a beautifully printed thank-you note on vellum paper inside the box, you can provide customers with an unboxing experience that exceeds their expectations.

Plastic Bag Packaging

If your socks will be displayed for retail sale, we recommend placing each pair in an individual clear bag (OPP or PE bag). This keeps them dust-free and allows customers to easily inspect them. However, this isn’t mandatory. Many clients choose to skip the clear plastic bag to be more environmentally friendly, or to make it easier for customers to directly touch and experience the fabric quality of the socks.

Additionally, if you’re doing corporate customization, employee benefits, or trade show giveaways, I sincerely suggest you consider a “multi-pair per bag” bulk packaging approach. We’ve witnessed far too much plastic waste on the production line. For socks being distributed to internal employees or given away as promotional items, eliminating individual plastic bags not only helps reduce your costs, but more importantly, it aligns perfectly with current environmental trends. Many large corporate clients now specifically request this from us, because it represents a tangible expression of corporate social responsibility.

Final Thoughts

There’s no absolute “best” packaging, only what’s most appropriate for your situation. Are you selling to price-conscious online shoppers, or gifting to important business partners? Will the socks sit on supermarket shelves, or be shipped directly to customers’ homes? These contexts determine which solution you should choose. As manufacturers, what we want most is to see your products succeed in the market. So if you’re uncertain about packaging dimensions, materials, or budget considerations, reach out to us anytime. We’ll use our years of experience to help you spend every dollar where it counts most.